| Standardization: | Numberical Symbol: | |

| AWS 5.15 | ENiFe-Cl |

|

| ASME SFA 5.15 | UNS W82002 |

|

| AWS Chemical Composition: | % | |

| Ni | 45-60 | |

| C | 2.00 | |

| Cu | 2.50 | |

| Mn | 2.50 | |

| Fe | bal. | |

| Al | 1.00 | |

| Si | 4.00 | |

| S | 0.03 | |

| Total others | 1.00 | |

| Standard values of the weld metal: | ||

| Elongation | % | 12 |

| Tensile strength | MPa | 490 |

| Yield strength | MPa | 365 |

| Applications: | ||

| Nickel Alloy Coated Electrodes is used for shielded-metal-arc welding of gray, ductile, malleable, and Ni-Resist cast irons. This electrode is also used for welding cast irons to various wrought materials including carbon steels, low-alloy steels, and nickel alloys. Nickel Alloy Coated Electrodes is useful for welding heavy sections and high-phosphorus irons. The welds are moderately hard and require carbide tipped tools for machining. This electrode can be operated in all welding positions. The power supply is direct current; electrode positive is preferred although alternating current can be used. | ||

| Make up: | ||

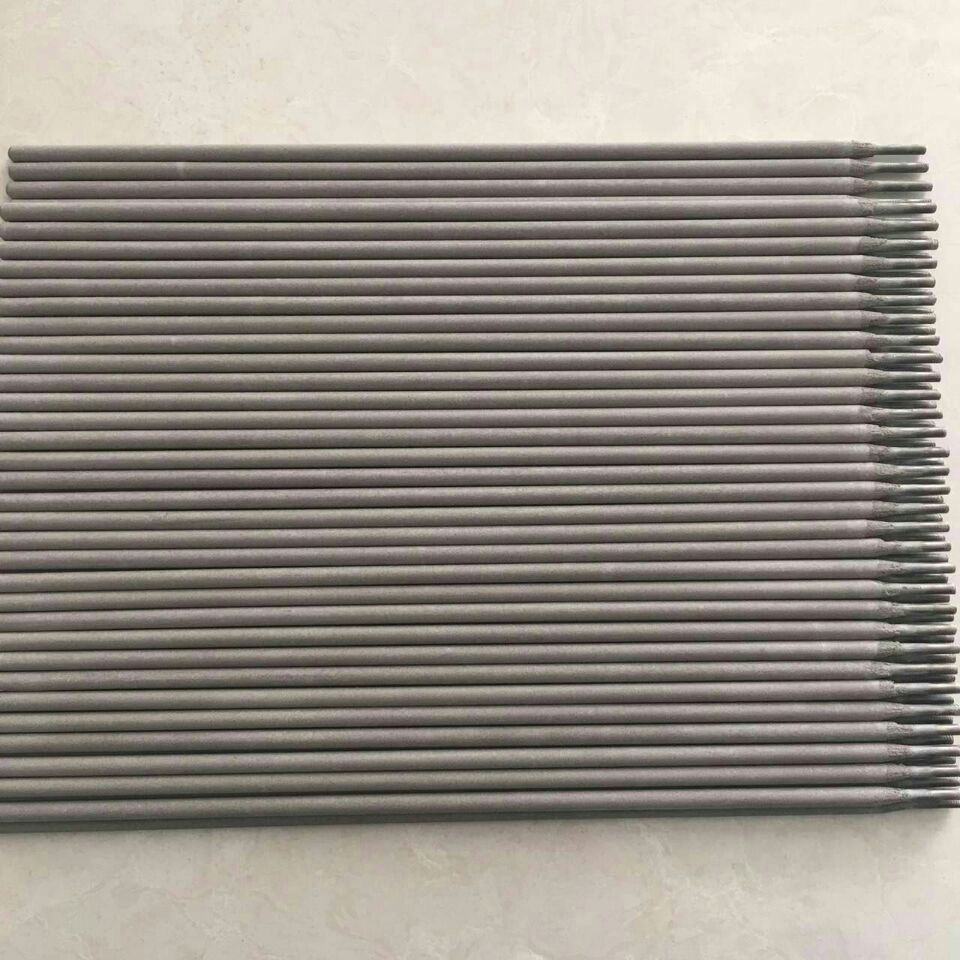

| Diameter: 1.60 -2.40 - 3.20 |

||

| Rods:1.60 - 3.2 mm x 300/350mm |

||

| Further make ups on request. |

||