| Standardization: | Numberical Symbol: | |

| AWS 5.10 | ER5356 | |

| ASME SFA 5.10 | UNS A95356 |

|

| AWS Chemical Composition: | % | |

| Si | 0.25 | |

| Fe | 0.40 | |

| Cu | 0.10 | |

| Mn | 0.05-0.2 | |

| Mg | 4.5-5.5 | |

| Cr | 0.05-0.2 | |

| Zn | 0.10 | |

| Ti | 0.06-0.20 | |

| Al | bal. | |

| other each | 0.05 | |

| Total others | 0.15 | |

| Standard values of the weld metal: | ||

| Elongation | % | 17 |

| Tensile strength | MPa | 269 |

| Yield strength | MPa | 132 |

| Applications: | ||

| Alloy 5356 is the most widely used welding alloy and can be classified as a general puroise type filler alloy. Alloy 5356 is typically chosen because of its relatively high shear strength. The 5xxx alloy base material, welded with 5356, with a weld pool chemistry greater than 3% Mg and service temperatures in excess of 150°F are susceptable to stress corrosion cracking. | ||

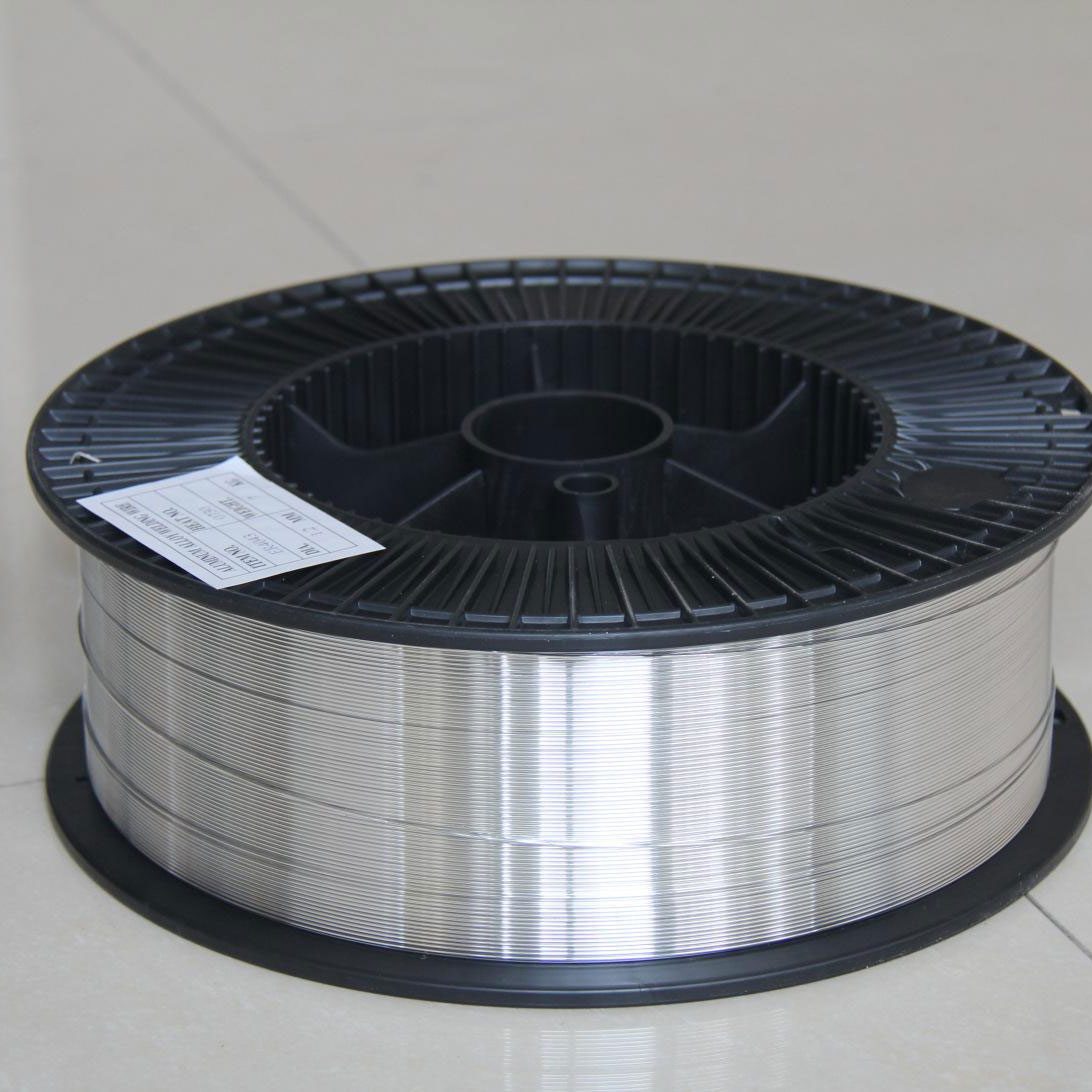

| Make up: | ||

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||