| Standardization: | Numberical Symbol: | |

| AWS 5.10 | ER1100 |

|

| ASME SFA 5.10 | UNS A91100 |

|

| AWS Chemical Composition: | % | |

| Si&Fe | 0.95 | |

| Al | ≥99 | |

| Cu | 0.05-0.20 | |

| Mn | 0.05 | |

| Zn | 0.10 | |

| other each | 0.05 | |

| Total others | 0.15 | |

| Standard values of the weld metal: | ||

| Elongation | % | 8 |

| Tensile strength | MPa | 187 |

| Yield strength | MPa | 125 |

| Applications: | ||

| Alloy 1100 is highly resistant to chemical attack and weathering. It is a relatively soft alloy that is very formable and is used extensively in thin gauge and foil products. It has good welding charac-teristics and it is also used as a filler alloy for welding purposes. A desirable charactristic of the alloy is the bright finishes obtained by anodizing. | ||

| Make up: | ||

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

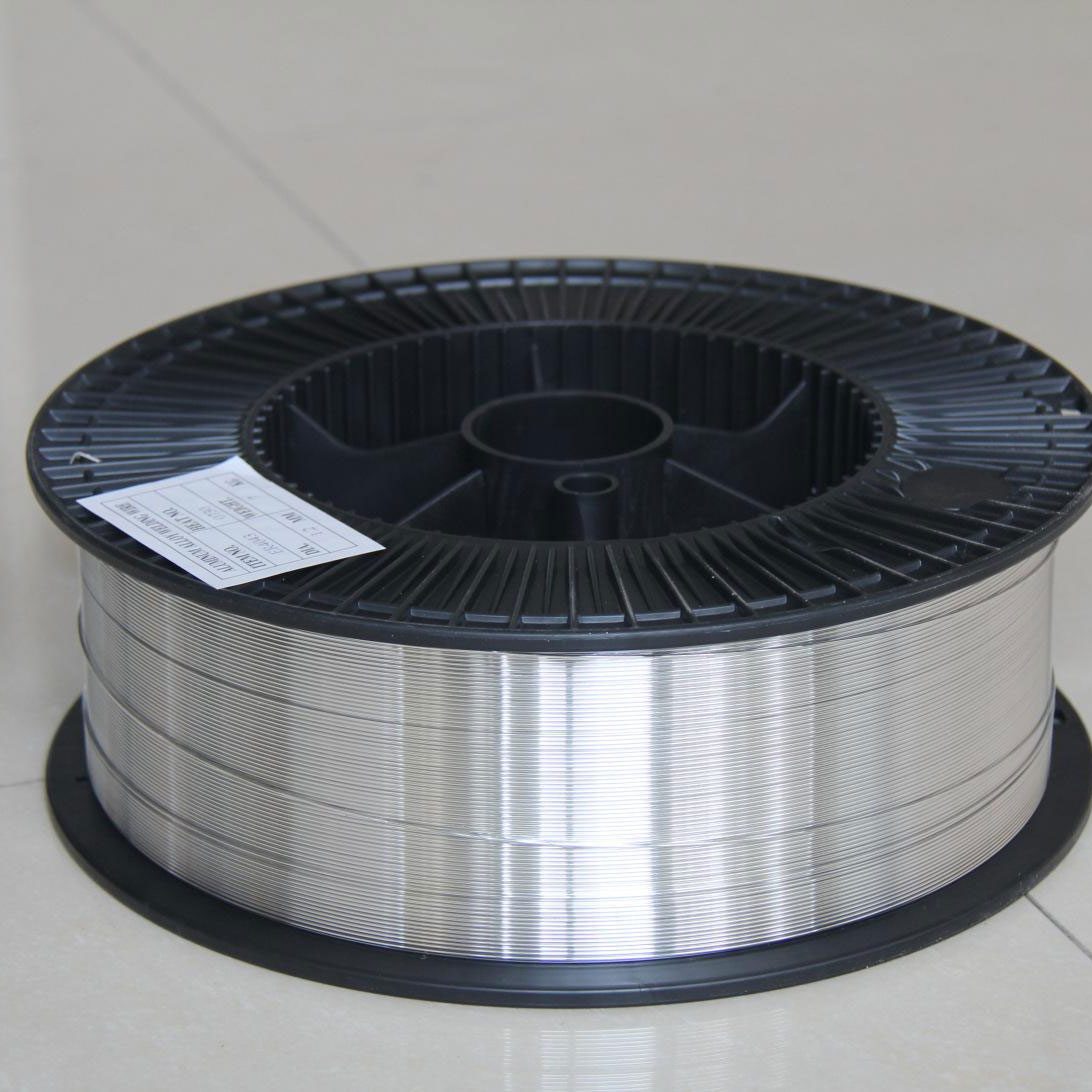

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||