| Standardization: | Numberical Symbol: | |

| AWS 5.10 | ER4047 |

|

| ASME SFA 5.10 | UNS A94047 |

|

| AWS Chemical Composition: | % | |

| Si | 11-13 | |

| Fe | 0.80 | |

| Cu | 0.30 | |

| Mn | 0.15 | |

| Mg | 0.10 | |

| Zn | 0.20 | |

| Al | bal. | |

| other each | 0.05 | |

| Total others | 0.15 | |

| Standard values of the weld metal: | ||

| Elongation | % | 8 |

| Tensile strength | MPa | 187 |

| Yield strength | MPa | 125 |

| Applications: | ||

| Alloy 4047 was originally developed as a brazing alloy (BAIAi-4) or (718) to take advantage of its low melting point and narrow freezing range. In addition, It has a higher silicon conternt than 4043, Which provides for increased fluidity and reduced shrinkage. The alloy produces bright and almost smut free welds. Hot cracking is significantly reduced when 4047 is used as a filler alloy. | ||

| Make up: | ||

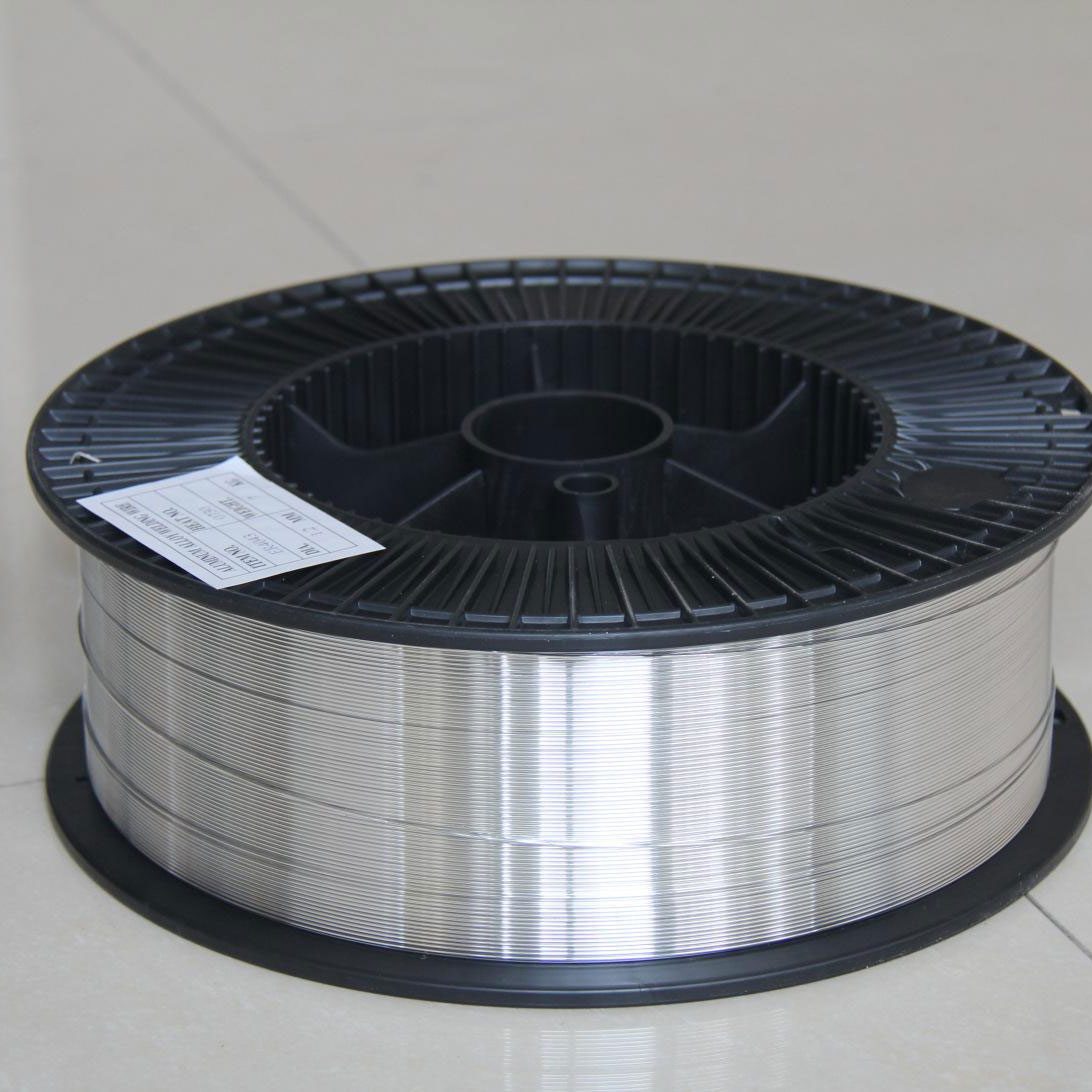

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||