| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu4701 |

|

| BS EN14640:2005 | Cu4701 | |

| BS Chemical Composition: | % | |

| Cu incl.ag | 58.50-61.50 | |

| Zn | bal. | |

| Sn | 0.20-0.50 | |

| Mn | 0.05-0.25 | |

| Fe | max 0.25 | |

| Si | 0.15-0.40 | |

| Al | max 0.01 | |

| Pb | max 0.02 | |

| Total others | max 0.20 | |

| Physical properties of materials : | ||

| Solidus | ℃ | 870 |

| Liquidus | ℃ | 880 |

| Brazing temperature range | ℃ | 915-945 |

| Applications: | ||

| Used on steels,copper,copper alloys,nickel,nickel alloys and stainless steel when corrosion resistance is not of importance.It is used with torch,furnace,and induction brazing processes.Fluxing is generally required,and a borax-boric acid type flux is commonly used. | ||

| Make up: | ||

| Diameter: 1.60 -2.40 - 3.20 - 4.00 - 6.35 - 7.93 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

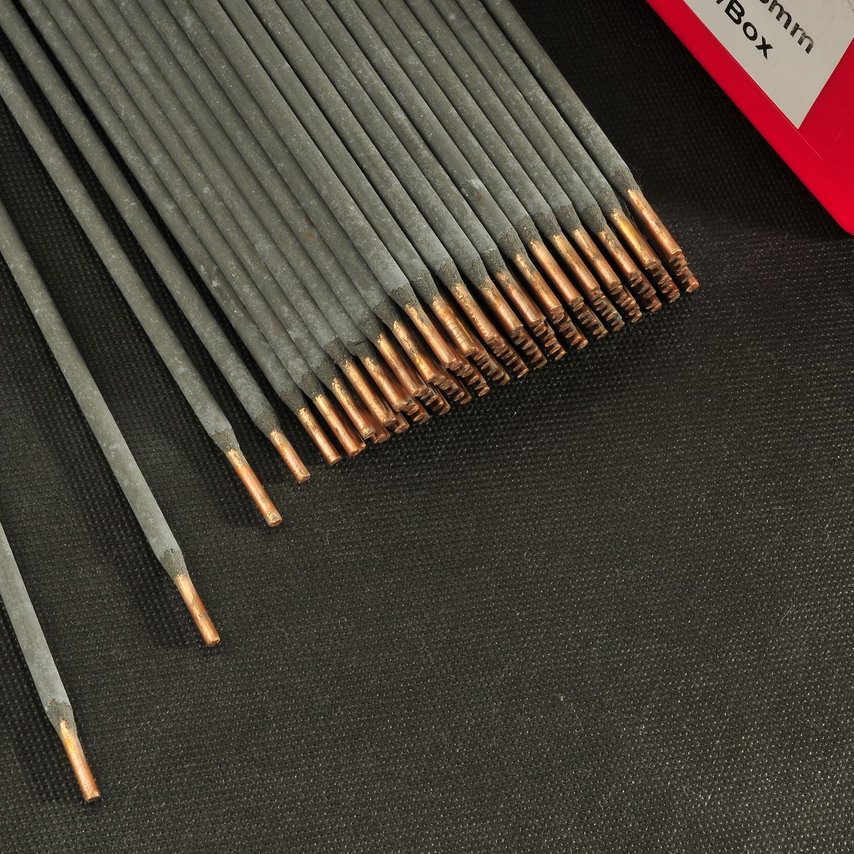

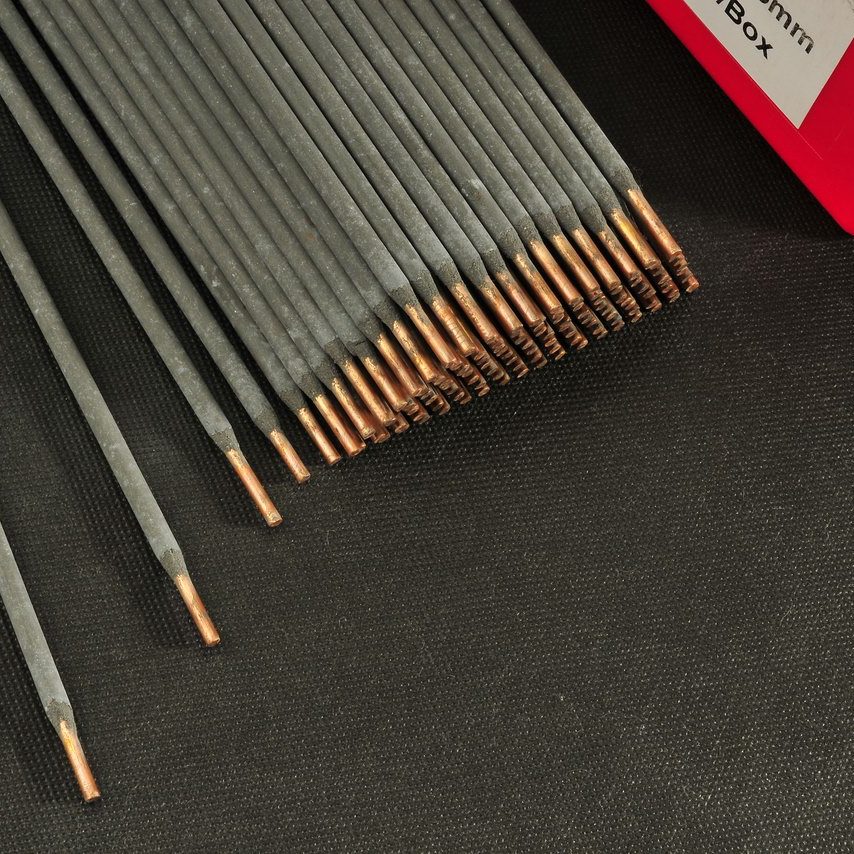

| Flux Coated and electrodes Available. | ||

| Further make ups on request. | ||