| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu6560 | |

| AWS A5.7:2007 | ERCuSi-A | |

| BS EN ISO24373:2009 | CuSi3Mn1 | |

| DIN 1733 | SG-CuSi3 | |

| AWS Chemical Composition: | % | |

| Cu incl.ag | bal. | |

| Zn | 1.00 | |

| Sn | 1.00 | |

| Mn | 1.50 | |

| Fe | 0.50 | |

| Si | 2.80-4.00 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Total others | 0.50 | |

| Physical properties of materials: | ||

| Density | Kg/m^3 | 3.5 |

| Melting range | ℃ | 965-1030 |

| Thermal conductivity | W/m.K | 35 |

| Electrical conductivity | S.m/mm^2 | 3.5-4.0 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 18.1 |

| Standard values of the weld metal: | ||

| Elongation | % | 40 |

| Tensile strength | N/mm^2 | 345 |

| Notched bar impact work | J | 55 |

| Brinell hardness | HB 2.5/62.5 | 80 |

| Applications: | ||

| Joining and overlay welding of copper zinc alloys,low copper materials,also for an excellent wear resisting overlay welding on low and unalloyed steel as well as cast iron.For MIG overlay welding of large work pieces preheating is recommended.For multilayer welding on steels,pulsed arc welding is recommended.Appropriate for MIG brazing of zinc coated sheets. | ||

| Make up: | ||

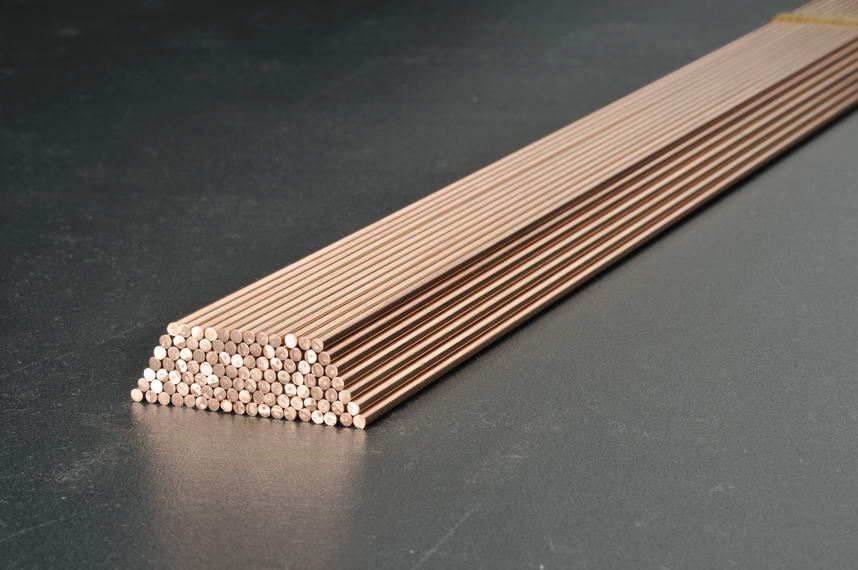

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

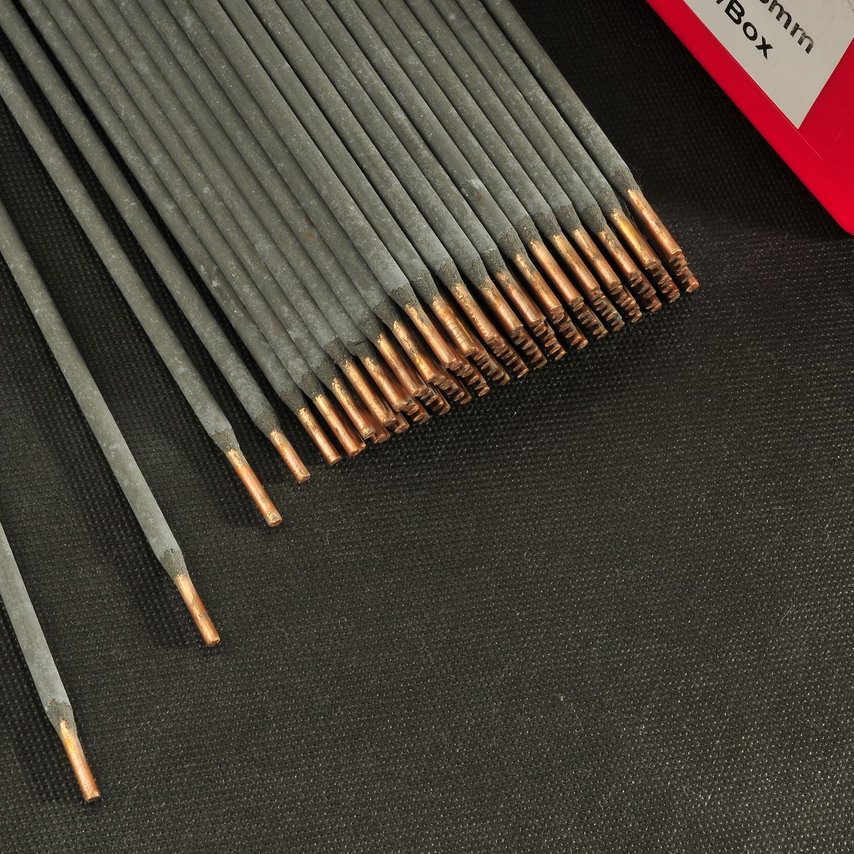

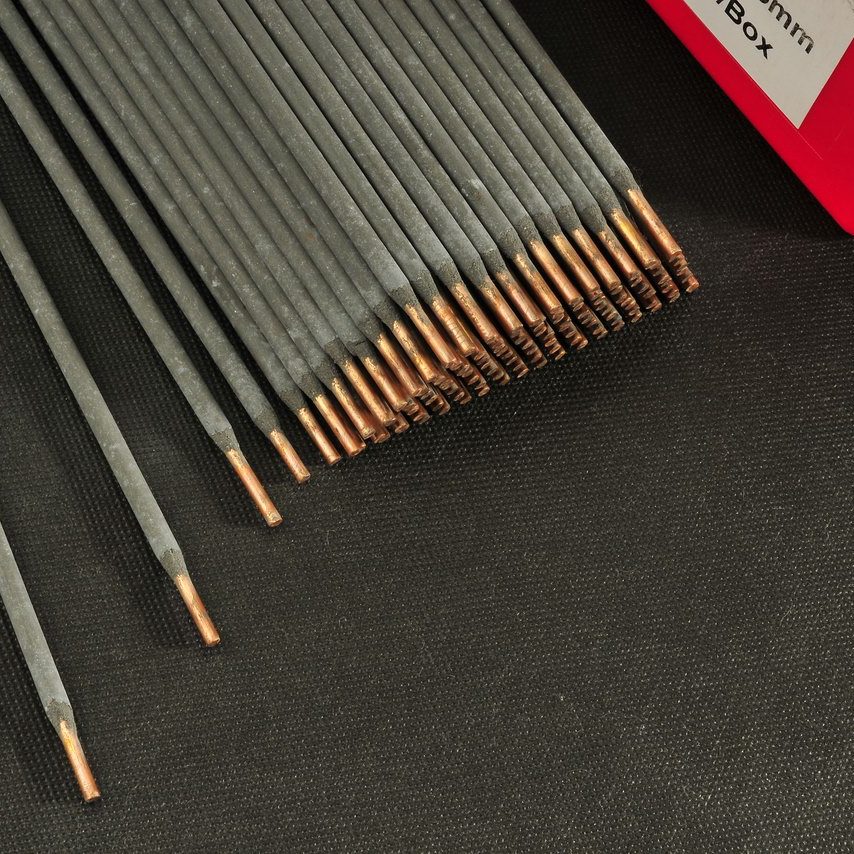

| Electrodes available. |

||

| Further make ups on request. |

||